Kalmar introduces significant updates to the Electric Straddle Carrier Charge Family

Kalmar has announced a major update to its electric straddle carrier charge family. The current battery options for electric straddle carriers will be consolidated to the single Gen 2 lithium-ion battery with approximately 25% higher capacity at equivalent cost. The new battery is complemented by the first Megawatt Charging System (MCS) for electric straddle carriers, as well as several supporting solutions for equipment monitoring and charge scheduling.

Gen 2 battery announced

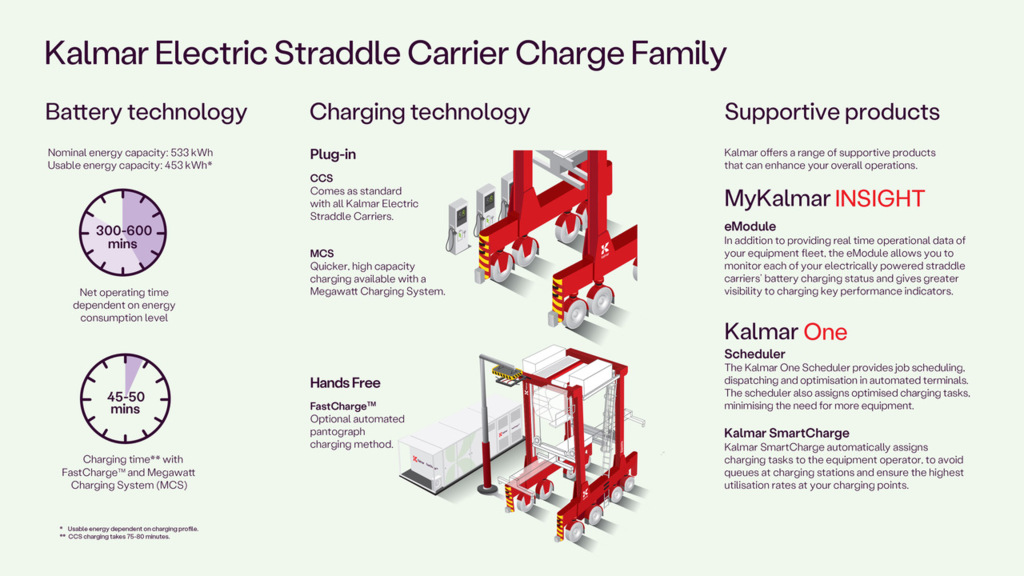

In December 2025, Kalmar announced its new Gen 2 battery for electric straddle carriers, which offers approximately 25% higher capacity than Kalmar’s previous High Energy battery for straddle carriers but at the same price point. The new battery will replace the two different batteries that were previously part of Kalmar's electric straddle carrier offering. With a nominal capacity of 533 kWh, the Gen 2 battery enables five to ten hours of operating time depending on machine load and operational conditions. The new battery is available to customers globally.

"Based on customer feedback and our experience, we expect that the longer continuous operating times enabled by the Gen 2 battery will be the preferred choice for terminals running electric straddle carriers," says Marko Hopeaharju, Head of Horizontal Transportation Solutions, Kalmar. "The new Gen 2 battery also supports fast charging with hands-free FastCharge or MCS interfaces, so we can now accommodate any charging scenario with a single battery type that offers more capacity and flexibility, without increasing the cost of the machine."

Based on customer feedback and our experience, we expect that the longer continuous operating times enabled by the Gen 2 battery will be the preferred choice for terminals running electric straddle carriers

Megawatt charging is a reality

Kalmar also announced the introduction of the first Megawatt Charging System (MCS) for electric straddle carriers. The solution, currently undergoing testing at Kalmar's test site in Tampere, enables much faster charging of straddle carriers compared to the traditional CCS interface. This allows terminals to charge more vehicles during breaks, simplifying scheduling and maximizing uptime. Reduced charging times have a direct effect on machine availability, lowering the total cost of ownership of the fleet.

The Kalmar Megawatt Charging System has been developed in partnership with Kempower, a leading manufacturer of EV charging solutions based in Finland. The first customer deployment of the solution is at DP World's London Gateway container terminal on 12 new Kalmar electric straddle carriers equipped with the MCS interface, currently under final commissioning at the site.

"CCS charging will remain the standard solution that is available on all Kalmar electric straddle carriers, but alongside it, the MCS and the hands-free FastCharge system open up significant new operational possibilities for terminals," says Marko Hopeaharju. "We are also developing the Automated Megawatt Charging System, which will further extend the charging options available for automated straddle carriers."

CCS charging will remain the standard solution that is available on all Kalmar electric straddle carriers, but alongside it, the MCS and the hands-free FastCharge system open up significant new operational possibilities for terminals

Supporting products

The ports and terminals industry is currently in the process of working out the standards and operational concepts that will enable zero-emissions operations with battery-electric container handling equipment. Higher battery capacity, faster charging times and smart charge scheduling are three of the most significant technological development areas for electric straddle carriers, and Kalmar's new charging solutions family addresses these needs directly.

The new battery and charging offerings are complemented by several supporting products including Kalmar SmartCharge, a solution that automatically assigns charging tasks to equipment operators to prevent queues at charging stations and to maximize utilization of charging points. Other supporting products for the Electric Straddle Carrier Charge Family include the eModule for the MyKalmar INSIGHT solution, which enables detailed monitoring of the charge status of each straddle carrier; and the Kalmar One Scheduler, which provides job scheduling, dispatching and optimisation in automated terminals. The Scheduler also assigns optimised charging tasks for automated equipment, minimising the required fleet size.

"Based on experience from customer terminals around the world, we expect that the predominant charging strategy for electric straddle carriers will be a mix of centralised depot charging over scheduled breaks, and smart opportunity charging during operations," says Sami Yli-Äyhö, Senior Manager, Product Management, Kalmar. "With the combination of our next-generation battery technology, fast megawatt-level charging with the MCS interface, and smart charging solutions, we are taking a significant step towards making electric straddle carriers even more attractive for ports and terminals of various sizes and operational profiles."

With the combination of our next-generation battery technology, fast megawatt-level charging with the MCS interface, and smart charging solutions, we are taking a significant step towards making electric straddle carriers even more attractive for ports and terminals of various sizes and operational profiles.

Related articles

Further reading

Customer case

Subscribe and receive updates in your email

Subscribe