Virtual environments: What would you like to see – in advance?

Visualisation is a broadband connection to the brain, as someone has wisely stated. Today, simulators and visualisation environments offer powerful means for testing and understanding the functionality of complex multi-technical systems.

The development of mechanical engineering tools has progressed from the first finite-element modelling (FEM) applications without graphical user interfaces to wireframe CAD and current real-time multi-body dynamics simulations.

Models of complete cranes and other machinery can now be driven with models of onboard control systems that, in turn, receive commands from models of high-level automation solutions. Or, the control and automation systems can be real, and only the crane mechanics and energy systems simulated. The combination depends on what is being developed and at which stage.

Camera adjustments with RTG (rubber-tyred gantry crane) simulator and remote control desk

Virtual is reality

The huge advances in the performance and stability of modelling and simulation applications have naturally had a tremendous impact on product development. Thanks to simulation, engineers can now safely accept smaller margins of error and build fewer physical prototypes. But the big thing is the ability to see the operation of proposed solutions.

A virtual yard crane moving containers in a properly visualised virtual environment – in real time – makes it possible to really understand what the new solution is about. It also makes it easier to judge whether the planned improvements in productivity, energy efficiency or safety can be realised in the proposed system.

Developments in augmented reality even make it possible to visualise simulated cranes operating in an existing terminal alongside current machines.

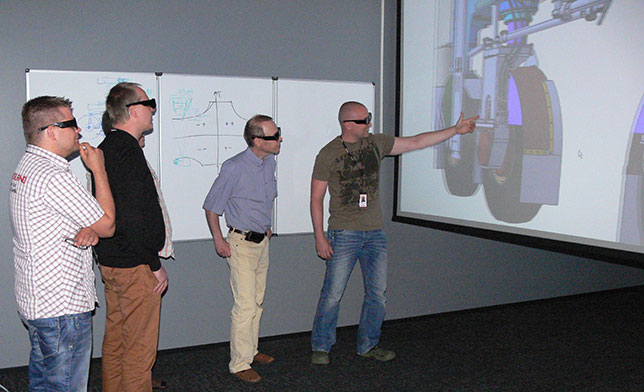

A driveline engineer demonstrating ease of access to maintenance staff. 3D visualisation with shutter glasses helps in perceiving depth.

From game console to container port

The rapid progress of game engines and the entire gaming industry has fuelled development in simulation and visualisation in several ways. Easily accessible and computationally efficient tools allow for impressive graphics, the smooth visualisation of multiple moving objects and highly realistic 3D environments.

People already expect game-like experiences

These visualisations can be combined with models and simulations run in engineering applications to produce highly immersive systems. They can also be combined with virtual environment hardware developed for gaming. People already expect game-like experiences from other virtual environment applications, and these expectations will force engineers to offer more realistic visualisations in their technical simulations.

Safety study in a virtual terminal with a head-mounted display

What do you want to know today?

Even if all of this is exciting, the wow effect is not the important thing to consider when evaluating the value of realistic visualisations and other factors contributing to convincing virtual environments.

Already with the first driving simulators it was noticed that immersion – the feeling of presence provided by the simulator – needed to be at a sufficient level to enable the simulator user to stop paying attention to the simulator and to focus on the actual operating task. A terminal expert observing a real-time animation of a productivity simulation needs to be able to concentrate on the performance of the visualised operation, without being distracted by obvious shortcomings in the working environment or machine models.

It’s all about asking the right questions. The best question that Big Data experts can ask of their customers is this one: “What would you like to know about your system?” The professionals developing and implementing virtual environments can ask their customers, “What would you like to see – in advance?”

Go ahead. Challenge your system suppliers to show more.

The writer manages simulator and visualisation environments development and implementation projects in Kalmar, Offering Development.

Related articles

Subscribe and receive updates in your email

Subscribe