Shares

-

This is Kalmar

We're moving cargo, our industry and our world further.

-

We're making every move count

We move heavy materials in critical supply chains around the world.

Our purpose

The logistics industry is transforming to meet the challenges of our world. At Kalmar, we are at the cutting edge of this transformation. With our global reach, we are driving sustainable material handling, creating value for our shareholders, and helping our customers improve their safety, sustainability and productivity.

Our vision

Our vision is to be the forerunner in sustainable material handling equipment and services.

Through our portfolio of efficient and decarbonised equipment, extensive service offering, and deep-rooted industry expertise, we focus on helping customers meet their sustainability and productivity targets.

Together, we’re making every move count

In everything that we do, we are powered by operational excellence, equipped by our inclusive culture and continuous focus on profitable growth. Our talented teams are empowered, energised, and ready to advance our customers’ success and move the world further.

Kalmar moves heavy materials in critical supply chains around the world

By continuously supporting our customers around the world as they are developing their operations towards safe, decarbonised and efficient supply chains, we strive to be our customers’ preferred partner in all their heavy material handling needs.

We offer a wide range of industry shaping heavy material handling equipment and services to ports and terminals, distribution centres, manufacturing and heavy logistics.

Our solutions

Show all

Operations

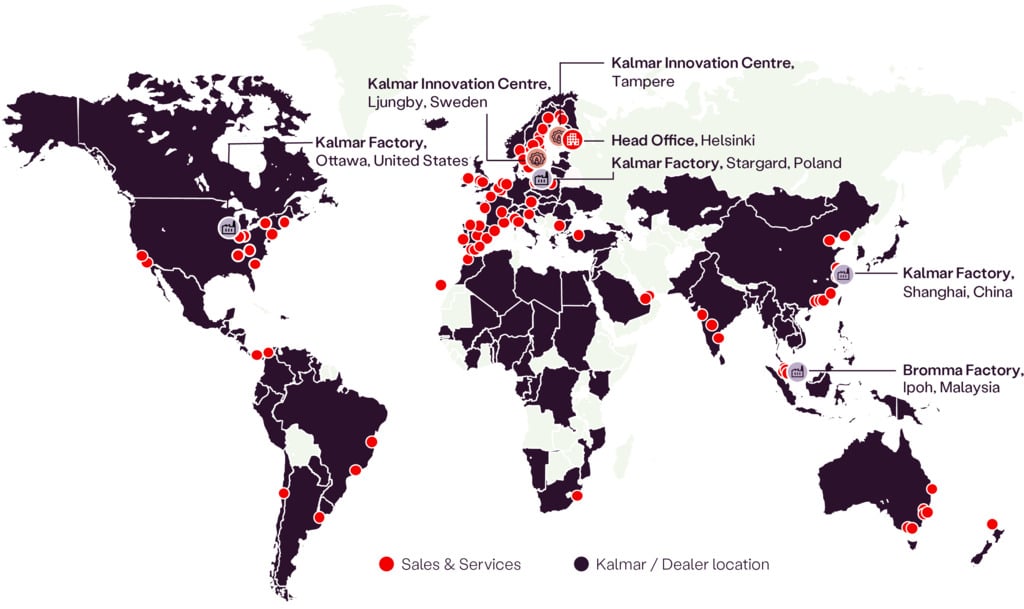

Kalmar operates globally in over 120 countries. It has facilities in multiple locations with its headquarters in Helsinki. Kalmar's factories are located in Poland, China, Malaysia and the United States. Kalmar has Innovation Centres in Tampere, Finland, and Ljungby, Sweden.

Read more